SEI Industries’ invention of the Bambi Bucket in 1982 revolutionized aerial firefighting and continues to be the world’s only collapsible bucket that combines multiple drop capability with both foam injection systems and shallow fill capability.

Since that time, this innovative company based in Delta, British Columbia, Canada, has kept improving the Bambi bucket system while developing new accessory innovations to support the industry. SEI Industries’ enhancements include foam injection systems, shallow water dip site Powerfill pumps and multiple drop, gated valves like Bambi MAX that allow the pilot more control with new capabilities to drop multiple, partial loads or full salvo drops on the fire.

Today, SEI Industries’ Bambi MAX bucket technology with the new Bambi Master Controller combines all of these improvements into one platform. The Bambi MAX gives pilots an aerial firefighting bucket system that comes with all the additional features and functionality they need to make their mission more effective in supporting the fire suppression efforts.

“Traditionally, the water drops on the Bambi MAX were executed manually using ‘time on trigger’ by the pilot,” said Shawn Bethel, SEI Industries’ aerial firefighting division manager.

“Given the complexity of operations that can be required on any given fire incident, the Bambi Bucket needs to be able to do more–for example, sequential water drops of varying volumes and durations, access to dip sites closer to the fire line using Powerfill systems to pull bucket loads from dip sites that are otherwise too shallow to dip out of, plus injecting those bucket loads with fire suppressant foam–all creating a higher level of efficiency and effectiveness on the fire line.

“Making durable and collapsible aerial firefighting buckets and innovative accessories is our core business at SEI and we are always working with our customers and the agencies to identify what else we can do to make the Bambi Bucket better. We want to develop products that help support a higher chance of successful initial attack while also aiding the ground crews on the ‘long term’ sustained action fires.

“SEI is always striving to make sure that whatever we offer our customers has high utility and good value while remaining easy to use and still being ‘plug and play,'” said Bethel. “The new Bambi Master Controller is another tool in the toolbox and a step further in that direction.”

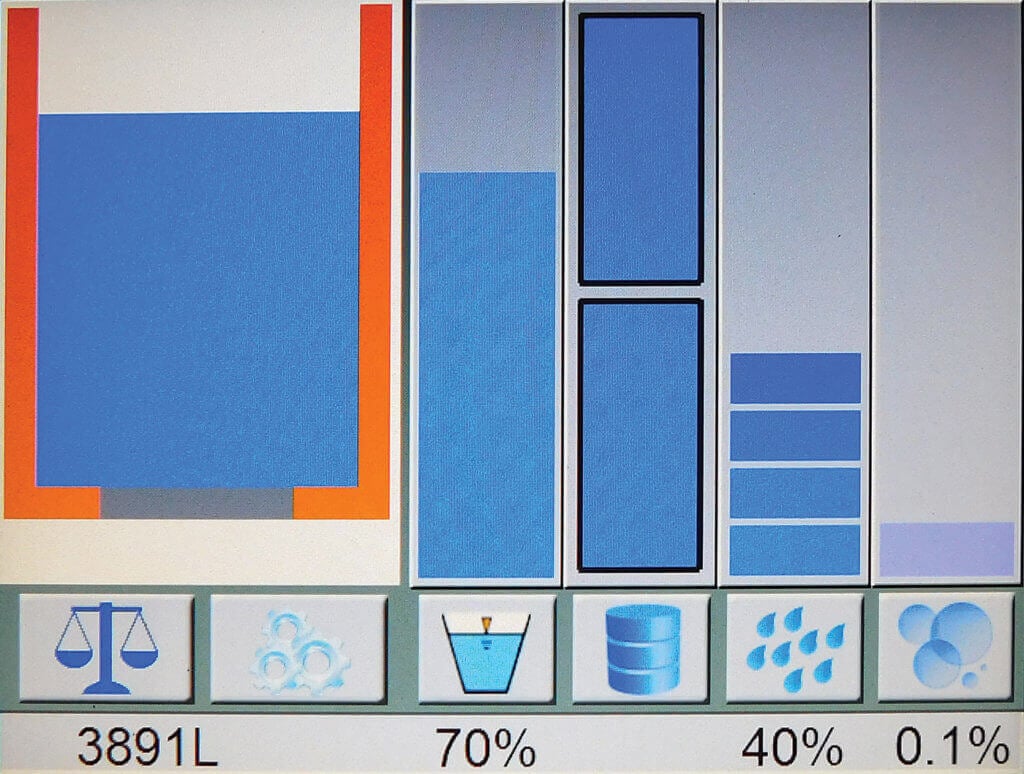

Using a resistive touch screen interface that measures 5.7 inches diagonally, the Bambi Master Controller connects to the Bambi MAX–equipped with new load sensing head and allows the pilot expanded functionality of the valve while using the same controller to also operate accessories like Sacksafoam and Powerfill. The additional valve functionality includes coverage level control (partial valve openings), automatic load shedding (water dip site), split drops over the active fire area or during the final ‘mop-up’ stage. The automated pre-select options can operate simultaneously but also have an override to ensure the pilot has full command of the bucket load every time.

Bethel said: “The new Bambi Master Controller is one of those enabling technologies that not only gives the pilot more performance and safety on the fire line but the fire management agencies, end-user of aerial firefighting contracts will benefit from the increased aerial firefighting performance that it offers. The net result sees more volume of suppressant or retardant on the fire-line as the bucket can carry more volume of water in the bucket as the helicopter burns down fuel (weight) on each turn through a fuel cycle. This net increase in the gallons per hour delivered to any given incident reduces the overall fire suppression costs.”

Another significant feature of the Bambi Master Controller system is its ability to adjust the amount of water captured during shallow dip site fills and to keep these loads in line with the helicopter’s total desired weight and expended fuel load. This maximizes water drop capacity without overworking the aircraft.

“We know from our customers that for reasons beyond just safety, the pilots simply cannot fill the bucket to 100 percent capacity with a full tank of gas and have the helicopter perform efficient firefighting in hot conditions at elevation — it’s simply too much workload on the helicopter,” said Bethel.

Using the sensors in the Bambi MAX load sensing head, the pilot can pre-select a desired capacity (zero percent to 100 percent) based on load calculations, factoring in all aspects of the mission requirement and the helicopter’s maximum load limitations. During each successive bucket fill, the Bambi Master Controller will automatically fill or shed weight to the desired setting pre-selected by the pilot. This selection can be changed on the fly and the pilot can override any setting to manual mode with a push of the valve actuation button on the cyclic or collective.”

The Bambi Master Controller automatically tracks how much water is loaded and subsequently dropped during the helicopter mission. This bucket data can be downloaded from the Bambi Master Controller onto a removable USB flash drive and then imported to an Excel spreadsheet or uploaded into whatever flight tracking program software the operator happens to be using.

“Having access to the bucket ‘event’ data in the non-volatile memory of the Bambi Master Controller will contribute to some extent towards the evaluation processes deployed by operators about their fleet mix and capabilities while agency staff have access to data that didn’t previously exist–all towards examining cost/benefit analysis of expensive aerial firefighting assets–assets that often account for 50 percent of overall annual fire suppression budgets in some jurisdictions,” said Bethel.

Despite its many features, the Bambi Master Controller is easy to install inside a cockpit, whether as a standalone display or integrated into the helicopter’s console.

“SEI’s electrical design R&D engineer chose the resistive touch screen interface display because it is so easy to use and clearly visible in all lighting conditions,” said Bethel. “Our goal is to expand the functionality of the Bambi MAX system, while making it easier for pilots to use while in flight. Given that so many government contracts call for Powerfill and gated Bambi Buckets already, it made sense for us to take this technology to the next level. That is precisely what the Bambi Master Controller does.”

If you would like to see your company featured in Insight, contact Derek Kast at derek@mhmpub.com.