When it comes to helicopter fuel systems, all available evidence suggests that having some crash-resistant features has a meaningful impact on reducing post-crash fires compared to having none at all. However, not all crash-resistant fuel systems (CRFS) are created equal, as is becoming apparent in the case of the Airbus AS350/H125 AStar series.

The AStar became the focus of a campaign to improve helicopter occupant protection following the fatal crash of a Flight For Life H125 in Frisco, Colorado, in July 2015. Although the model’s susceptibility to post-crash fires was a known problem at that point, dramatic video footage of the Frisco crash galvanized public attention, leading to the creation by the Federal Aviation Administration (FAA) of a Rotorcraft Occupant Protection Working Group (ROPWG).

Many of the ROPWG’s recommendations were incorporated into last year’s FAA Reauthorization Act, which requires CRFS for all helicopters manufactured after April 5, 2020. The law stipulates compliance with many, but not all, of the provisions in Federal Aviation Regulations (FAR) 27/29.952, which mandates CRFS standards for civil helicopters certified after 1994. The exceptions in the new law are intended to make it easier to certify CRFS for legacy models like the AS350 — which received initial FAA type certification in 1977 — while still providing substantially increased levels of occupant protection, as validated by the ROPWG’s analysis of post-crash fires in survivable accidents.

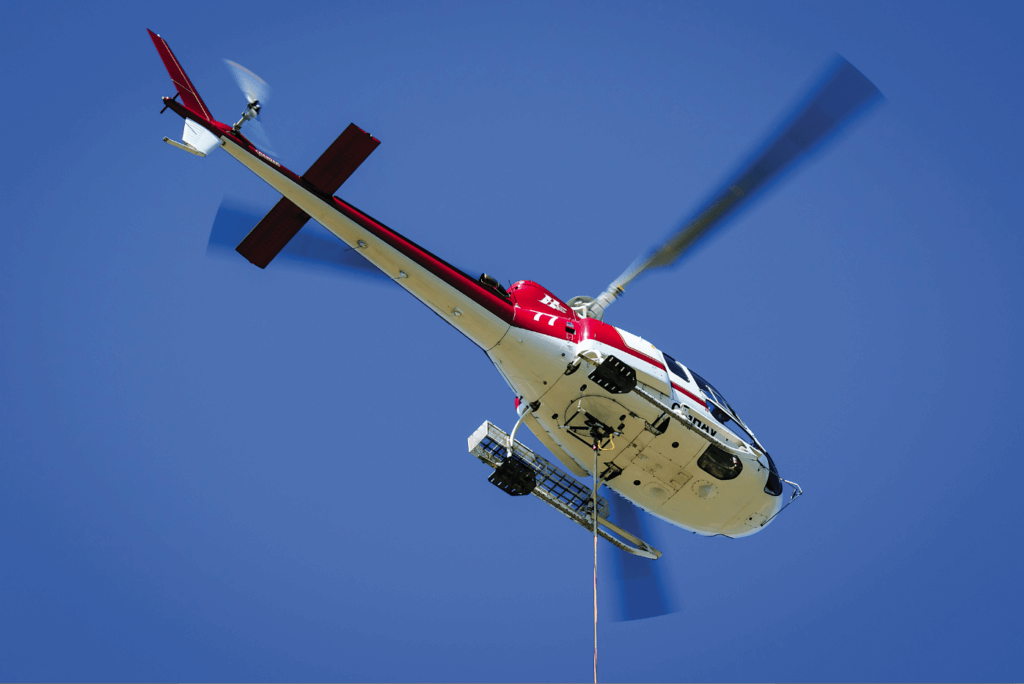

Indeed, complying fully with 27/29.952 is neither easy nor cheap. Airbus certified a retrofit kit solution for newly manufactured H125 (AS350 B3e) helicopters in 2014, but has not yet managed to certify it with the underbelly cargo swing installation used for external loads. The company declined to confirm a report that claimed the installation punctured the fuel system during drop testing, instead telling Vertical, “We are currently in the development phase in order to obtain 27.952 certification of the cargo swing installation and have no comments on specific tests.”

Airbus announced at HAI Heli-Expo earlier this year that starting in 2020 it will be making its CRFS standard on all newly-manufactured H125s, including those produced at its headquarters in Marignane, France (currently, the CRFS is only standard on H125s produced in the United States). Airbus also announced it will expand certification of its CRFS to AS350 B3 and EC130 B4 models in the same timeframe, and will offer the system at its own cost of $44,000.

The company told Vertical that it aims to obtain 27.952 certification of the cargo swing installation by then. “If this certification was to be delayed, for whatever reason, the standard implementation of our CRFS on all new H125s will be maintained so that all customers — including those equipped with a cargo swing — can benefit from this safety enhancement,” Airbus said, emphasizing that even for customers operating with a cargo swing, the CRFS offers significant safety enhancements over the legacy fuel system.

Meanwhile, there is a certified CRFS solution for AStar operators using cargo swings: the aftermarket product jointly developed by Robertson Fuel Systems and StandardAero, which was certified to the standards of 27.952 in December 2017. The Robertson/StandardAero tank is a direct replacement for all AS350 models, including the AS350 C, D/D1, B/B1/B2/BA/B3, H125, and EC130 B4. Although there was a year-long waitlist for the product when it first hit the market, Robertson ramped up production to meet demand, and now cites wait times of around 90 days.

According to Robertson Fuel Systems director of engineering Bill York, designing a tank that could pass the required drop tests with the cargo swing installed was the most challenging aspect of certification. Robertson has a long history of designing and certifying aircraft fuel tanks to more stringent military standards, but “in our previous experience we never had quite that challenging a thing underneath an aircraft or anticipated to be a penetrator,” he explained. “So that required multiple test drops and changes to the bottom construction of both the container and [the] machined aluminum sump plate which holds a lot of the mechanics and the boost pumps at the bottom of the tank.”

Elvis Moniz, StandardAero’s VP of business development for airframes and avionics, pointed to that additional engineering as a benefit to all customers of the tank, not just those who operate with cargo swings. The ability of the tank to resist puncturing could be extrapolated to other objects, he suggested: “So if you land on a rock, or a fire hydrant, or anything else than just a flat piece of concrete, that’s what we’re after. We’re actually trying to make this product as real-life survivable as possible.”

According to Robertson and StandardAero, while the Airbus system has a riveted aluminum container, their tank has a composite container shell strategically designed to help distribute impact loads in a crash. The Robertson/StandardAero tank also has some other premium safety features, including self-sealing breakaway valves, and a float-based rollover vent system that will close off in any abnormal orientation to prevent fuel from coming out of the vent. This is in addition to features intended to enhance the tank’s market appeal, including ease of installation, cartridge-style fuel pumps to improve serviceability, and compatibility with OEM and aftermarket fuel filters and baggage extenders, the companies said.

The catch: all of this comes at a cost. The Robertson/StandardAero tank is typically sold for between $100,000 and $120,000, around two-and-a-half times the cost of the Airbus CRFS. “I think a lot of people in this market have not had to plan their operations around the investment that’s needed to be crash-resistant, or been informed of the benefits and how they impact their operation,” noted Robertson sales and marketing manager Ashley Sanchez. “So part of this is getting the market comfortable with the requirements to meet the CRFS standards.”

Robertson, StandardAero, and Airbus declined to say whether Airbus may eventually incorporate the aftermarket tank into its production line for customers who want a more robust CRFS solution. In the meantime, however, Airbus is incentivizing operators of AS350 B2 and earlier models to purchase the Robertson/StandardAero tank by offering training credits to offset part of the cost.

“Customers having already installed CFRS kits on their fleet to whom the training credit might not apply are invited to get in touch with their local contacts so that we can evaluate their training needs and make specific offers,” Airbus said.