Last year, Safran Helicopter Engines obtained European Union Aviation Safety Agency (EASA) type certificates for the Arrano 1A (Airbus Helicopters H160), Aneto-1K (Leonardo AW189K) and Ardiden 1U (India’s LUH). Meanwhile, the WZ16 turboshaft received certification from the Civil Aviation Administration of China (CAAC).

“Obtaining four new certifications in one year is truly exceptional,” said Bruno Bellanger, executive vice-president, programs. “It demonstrates that Safran Helicopter Engines is fully committed to supporting entry-into-service of new helicopters with competitive and modern propulsive solutions.”

“Obtaining four new certifications in one year is truly exceptional,” said Bruno Bellanger, executive vice-president, programs. “It demonstrates that Safran Helicopter Engines is fully committed to supporting entry-into-service of new helicopters with competitive and modern propulsive solutions.”

Certification 2019

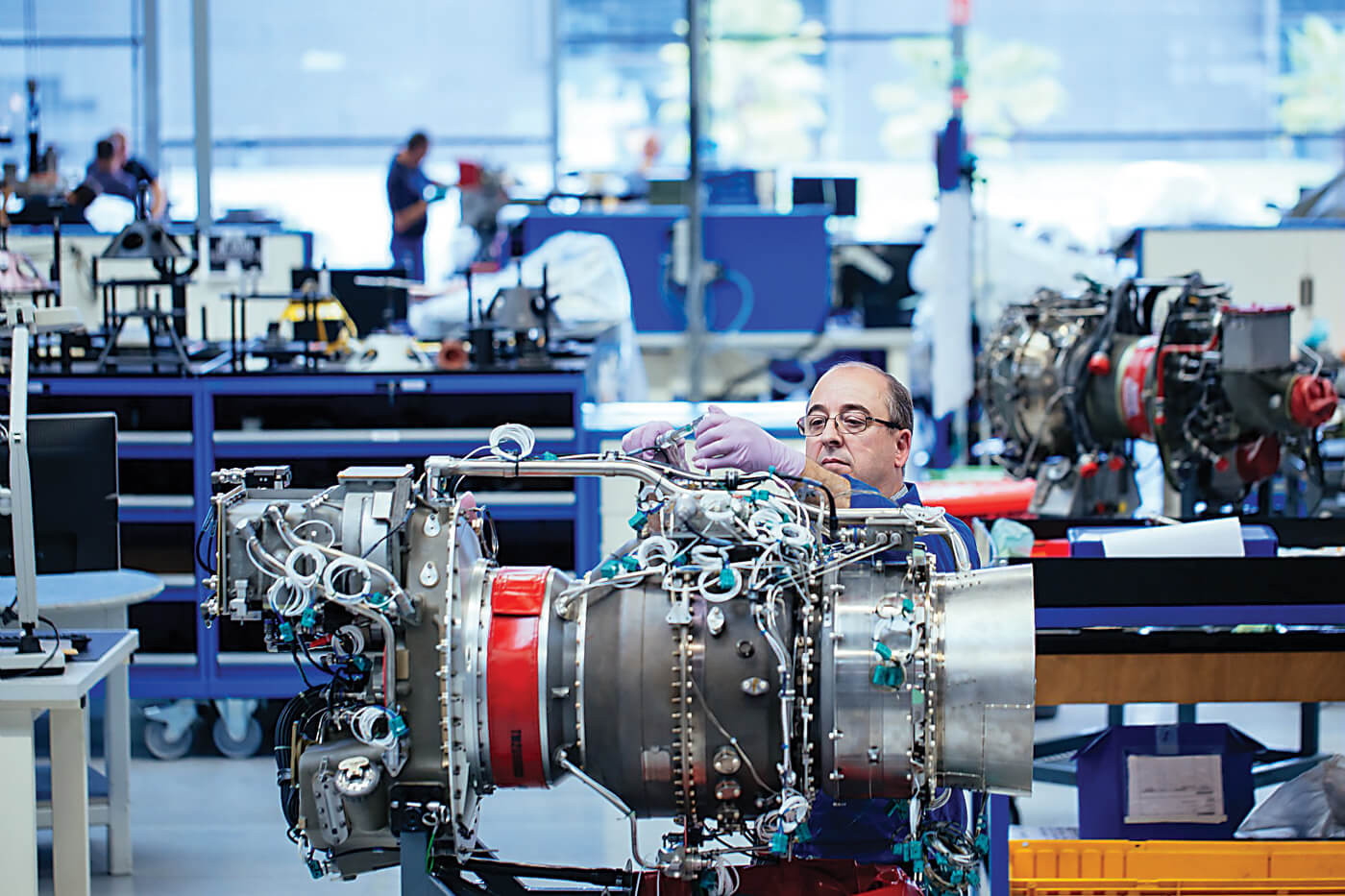

With its certification announced at the 2019 Paris Air Show, the Arrano stands at the vanguard of Safran Helicopter Engines’ new range. Its performance is unrivalled, and it features low operating and support costs, ease of maintenance and a reduced environmental footprint.

With an unprecedented test campaign of more than 10,000 hours, including more than 2,500 in flight, the Arrano is fully ready for H160 entry-into-service and the development of Guépard, the H160’s military variant. As with the civil H160, Guépard will feature two Arrano 1As, each capable of delivering 1,280 shaft horsepower (shp) at takeoff. U.S. Federal Aviation Administration certification of the Arrano is planned for 2020.

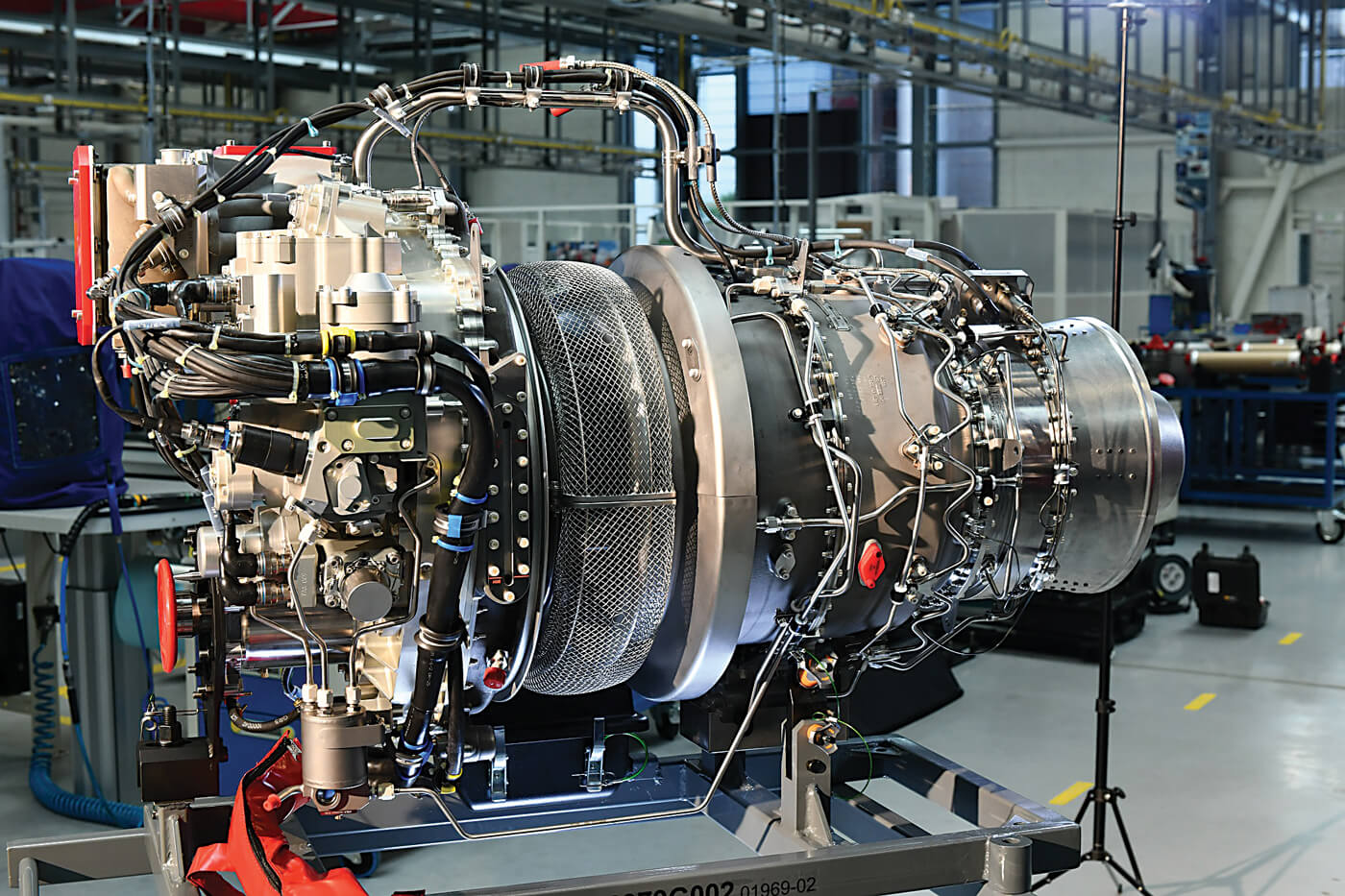

Certified on Dec. 12, 2019, the Aneto-1K is “the new kid on the block” from the French manufacturer. Developed for the Leonardo AW189K, it is the first variant of the 2,500-3,000 shp Aneto engine family. The 1K is rated at 2,500 shp and its first flight in the AW189K took place in March 2017.

The 1K demonstrates excellent performance and reliability and should be a major factor behind the predicted success of the AW189K. Thanks to an exceptional power-to-volume ratio, it delivers 25 percent more thermal power (compared to other similar engines), resulting in increased mission capabilities. This is especially useful in such demanding roles as offshore transport, search and rescue, firefighting, law enforcement or military transport and ensures increased hot-and-high power margins and solid performance in the transitory regime.

The 1K demonstrates excellent performance and reliability and should be a major factor behind the predicted success of the AW189K. Thanks to an exceptional power-to-volume ratio, it delivers 25 percent more thermal power (compared to other similar engines), resulting in increased mission capabilities. This is especially useful in such demanding roles as offshore transport, search and rescue, firefighting, law enforcement or military transport and ensures increased hot-and-high power margins and solid performance in the transitory regime.

Installed in India’s LUH (Light Utility Helicopter), the Ardiden 1U was certified on Oct. 31, 2019. The LUH is a new three-ton, single-engine, multipurpose rotorcraft designed by Hindustan Aeronautics Ltd. Since the Ardiden 1U’s first ground test in 2015, its maturation and certification campaign has accumulated about 1,000 hours on testbeds or in flight, confirming the high reliability and performance inherited from the 1H1. Last September, the LUH conducted hot and high tests in the Himalayas, demonstrating the 1U’s capability to deliver high rates of power in this particularly demanding environment.

Finally, on Oct. 10, 2019, Safran Helicopter Engines and the Aero Engine Corp. of China (AECC) received a type certificate for the WZ16 from CAAC. Installed in the AVIC AC352 helicopter, the WZ16 is the first-ever jointly developed aero engine to be entirely certified by Chinese authorities. Also known as the Ardiden 3C, the WZ16 is jointly developed and built by Safran Helicopter Engines and AECC consortium members Harbin Dongan Engine and Hunan Aerospace Propulsion Research Institute. The Ardiden 3C received EASA certification in April 2018.

“CAAC certification marks a major milestone for Safran Helicopter Engines and AECC,” said Bellanger. “It confirms that, thanks to an intensive maturation plan conducted by our partners, the WZ16 is now ready to operate to world-class Chinese safety and performance standards. It is also a historic moment for the Chinese aerospace industry . . . and a major step toward AC352 entry-into-service.”

“CAAC certification marks a major milestone for Safran Helicopter Engines and AECC,” said Bellanger. “It confirms that, thanks to an intensive maturation plan conducted by our partners, the WZ16 is now ready to operate to world-class Chinese safety and performance standards. It is also a historic moment for the Chinese aerospace industry . . . and a major step toward AC352 entry-into-service.”

Turboprops, 3D Printing and Hybrids

In parallel with its intensive development certification plan, Safran Helicopter Engines remains at the leading edge of new aero-engine technologies.

During the 2019 Paris Air Show, the OEM introduced Add+, an engine technological demonstrator with 30 percent of its components made using additive manufacturing (3D-printing) techniques. The result of a partnership between several Safran Group companies, Add+ will enable 3D-printed parts to be used in Group production engines. Development started in early 2018 and ground tests are now in progress.

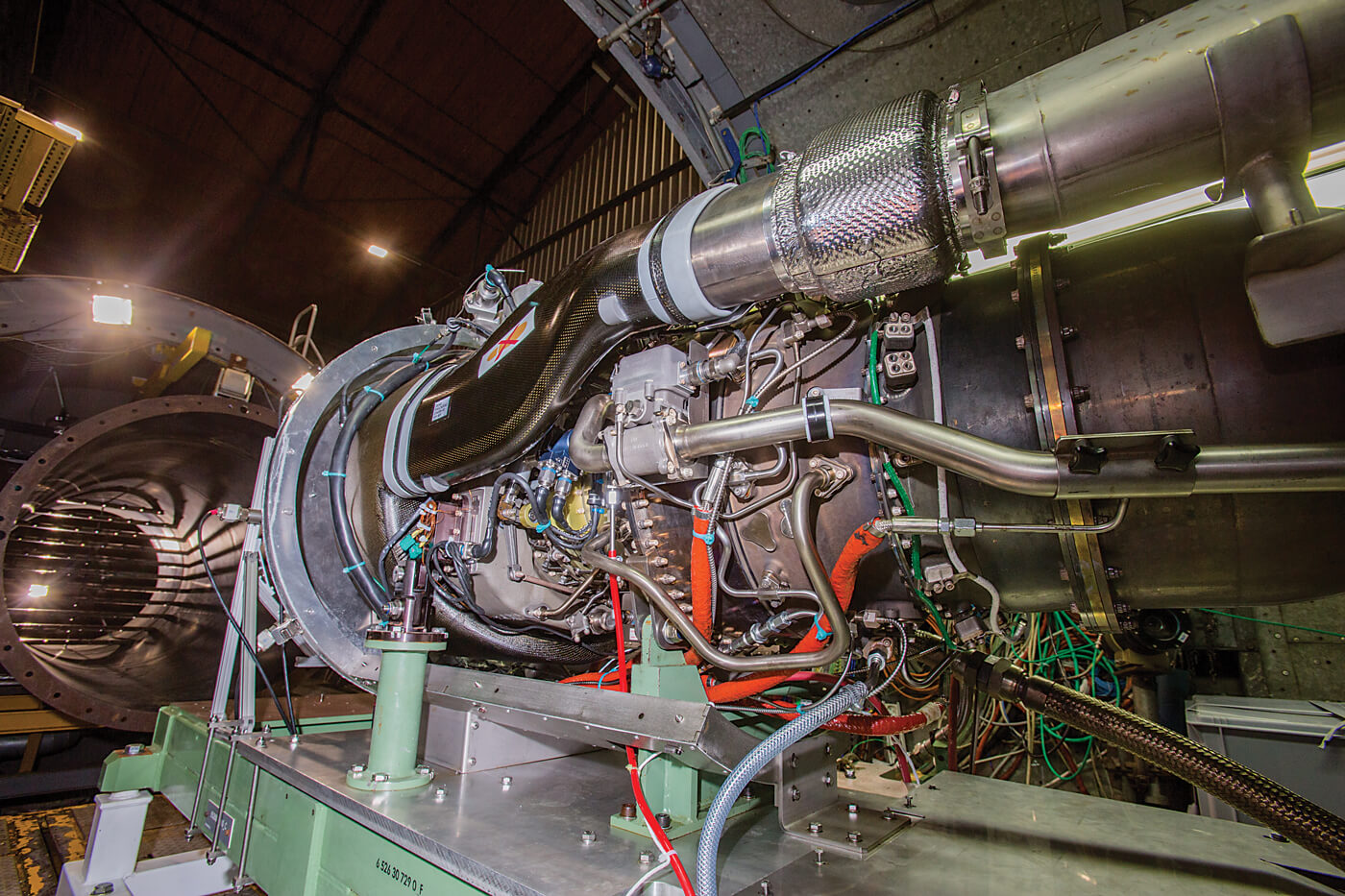

In June 2019, Safran Helicopter Engines also started ground testing of its Tech TP, a turboprop technological demonstrator based on the Ardiden 3 turboshaft and developed as part of Europe’s Clean Sky 2 research and innovation program. The test took place at Safran Helicopter Engines’ facility in Tarnos (France). More than 20 European partners are contributing to this demonstrator, which aims to validate the technologies for a new-generation turboprop, capable of delivering 15 percent lower fuel consumption and CO2 emissions, and featuring a unique throttle and a full authority digital engine and propeller control (FADEPC) for both power and propeller pitch.

In June 2019, Safran Helicopter Engines also started ground testing of its Tech TP, a turboprop technological demonstrator based on the Ardiden 3 turboshaft and developed as part of Europe’s Clean Sky 2 research and innovation program. The test took place at Safran Helicopter Engines’ facility in Tarnos (France). More than 20 European partners are contributing to this demonstrator, which aims to validate the technologies for a new-generation turboprop, capable of delivering 15 percent lower fuel consumption and CO2 emissions, and featuring a unique throttle and a full authority digital engine and propeller control (FADEPC) for both power and propeller pitch.

Safran Helicopter Engines is also pursuing its hybrid propulsion roadmap. In 2020, it plans to to ground-run a distributed propulsion system featuring a turbo-generator capable of producing 300 kWe. In parallel, alongside other Safran companies, Safran Helicopter Engines has been selected (with Airbus and Daher) to take part in the EcoPulse program to demonstrate a hybrid propulsion system on a fixed-wing aircraft.