Safran Helicopter Engines engineers in Bordes, France, are busy developing a new engine for heavy helicopters and are considering two successive versions — the first one being certifiable as soon as 2020. The second one could benefit from a hybrid combustion-electric architecture. The engine manufacturer’s innovation strategy can also be seen in the factory and may soon translate into far-reaching improvements in maintenance.

Safran currently has no offer above the 2,300-shaft horsepower (shp) RTM 322, which powers the NHIndustries NH90, the Leonardo AW101 and the U.K. Apache. Therefore, in the 2,500 to 3,000-shp power range, a two-step master plan is being rolled out. A 2,500-shp engine could be certified in 2020 thanks to an incremental evolution of existing technologies, according to Bruno Even, Safran Helicopter Engines’ CEO. The time frame and information previously released by the company suggest the turboshaft is already running on a ground test bed. The still-under-wraps Airbus Helicopters X6, which should replace the Super Puma family, is a likely target.

Higher in the power range, between 2,800 and 3,000 shp, Safran’s design bureau will need more time. It is targeting a 25 percent improvement in fuel consumption. A hybrid architecture could help. The idea is to shut down an engine in cruise flight (or let it run at idle power) for better overall efficiency and restart it very quickly, if needed. Ideally, full power could be regained within 10 seconds.

Safran ran a hybridized RTM 322 on a test bed last year. Flight trials could take place in 2020 to 2021. A hybrid engine could then be in production in 2025.

The advent of more futuristic, multi-rotor prototypes has driven Safran’s engineers into the topic. A 100-kilowatt (135-shp) multi-rotor system is planned to be tested in 2018. Electric motors will drive the rotors, but a turboshaft will supply electric power. Fuel-burning engines will thus remain predominant for another 30 to 40 years, Even predicted.

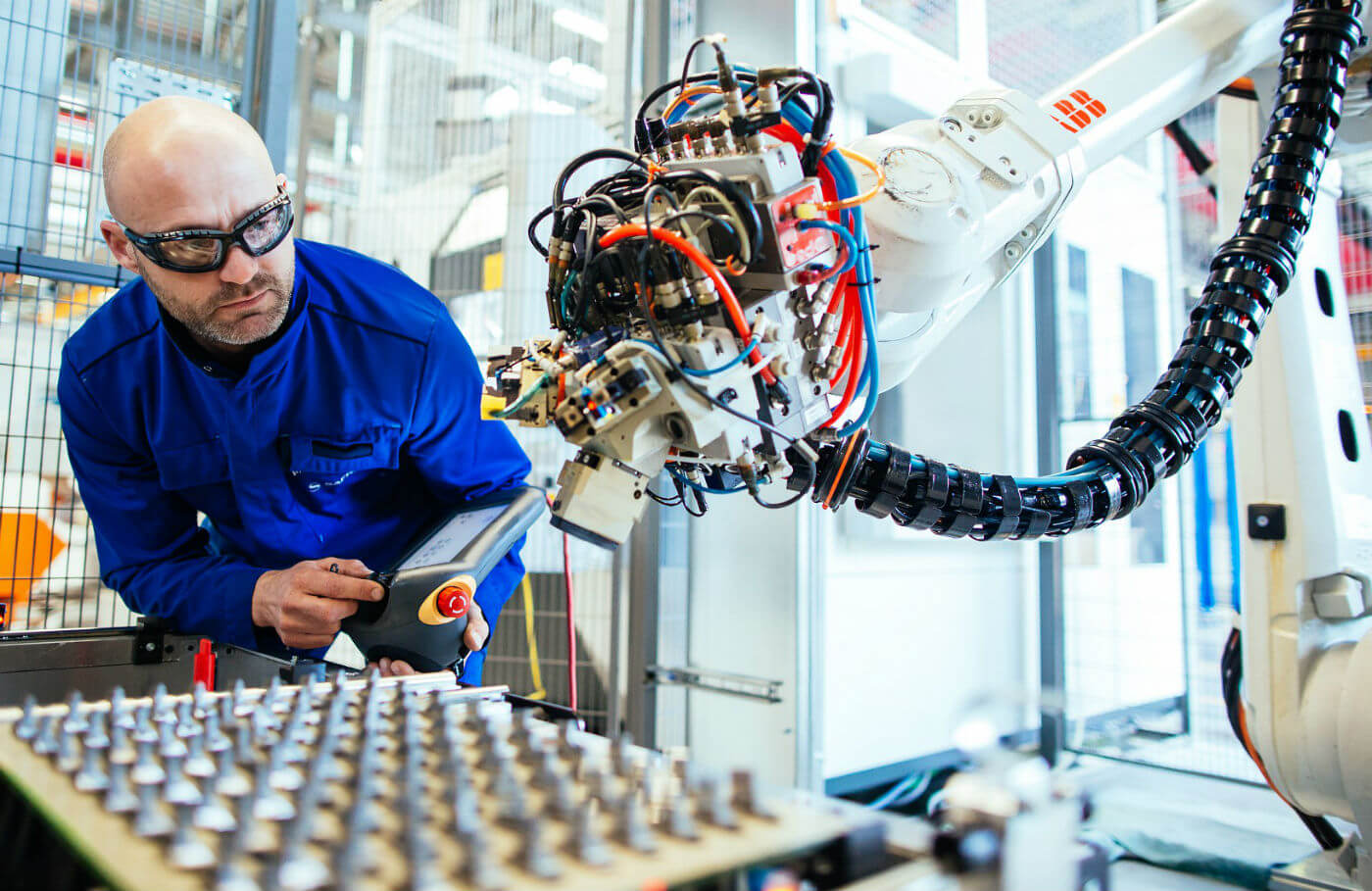

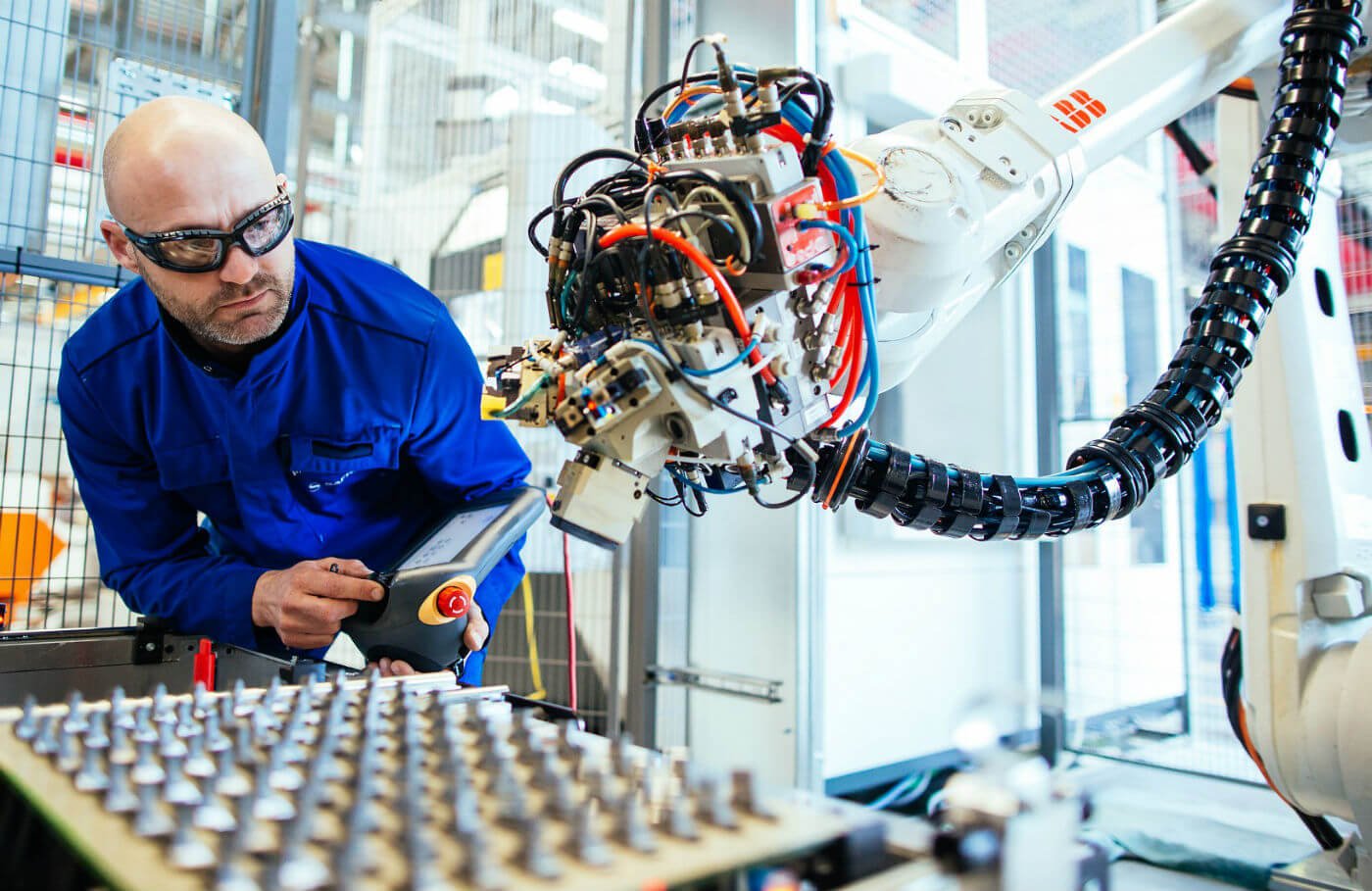

In the factory, a highly automated production line for turbine blades was inaugurated last December. As a result, the production cycle has been halved and the scrap rate has been divided by four. The new production line’s capacity is more than 100,000 airfoils per year.

Instead of cutting jobs due to automation, Safran said it has hired another six workers. Some have been trained in robotics, to gain independence from maintenance service providers in automation.

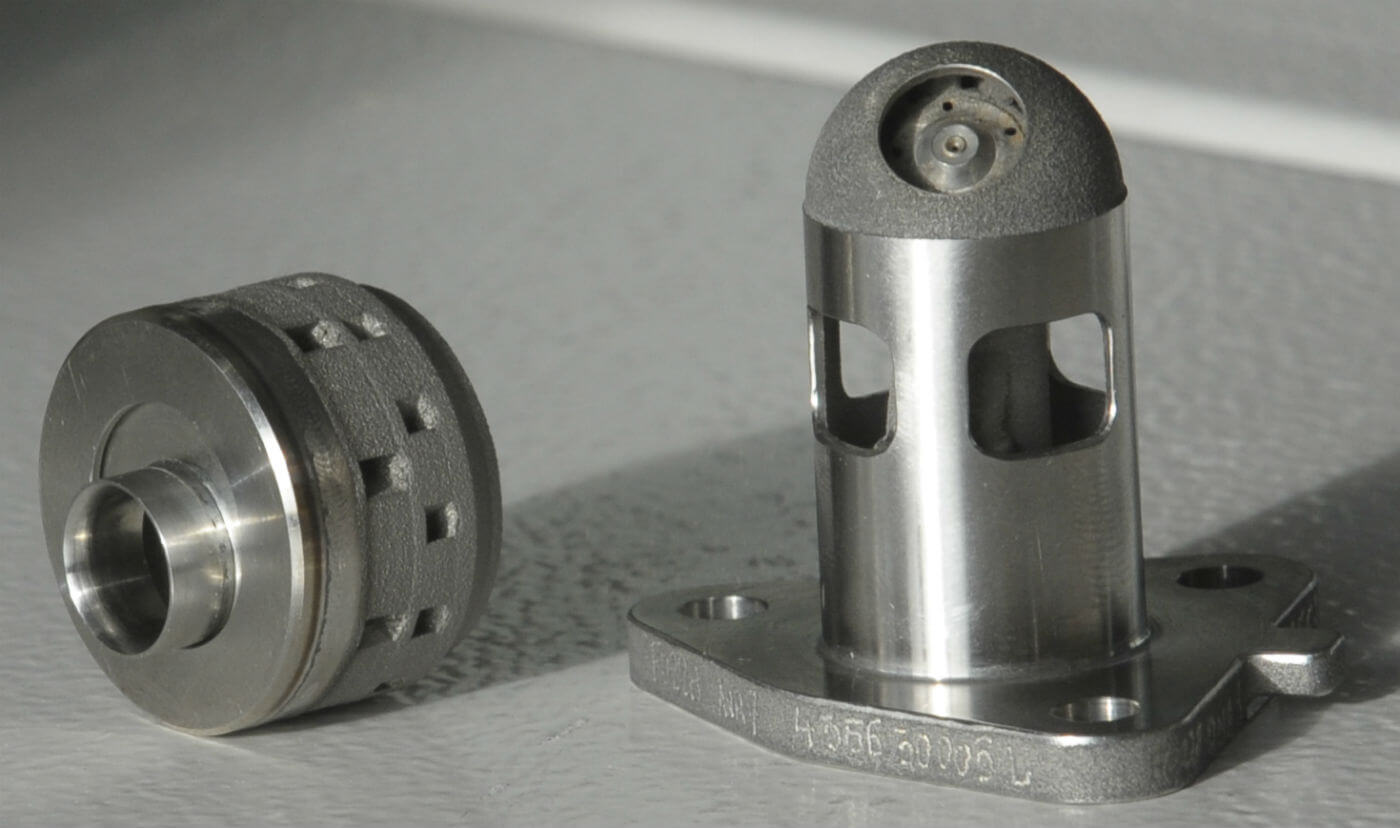

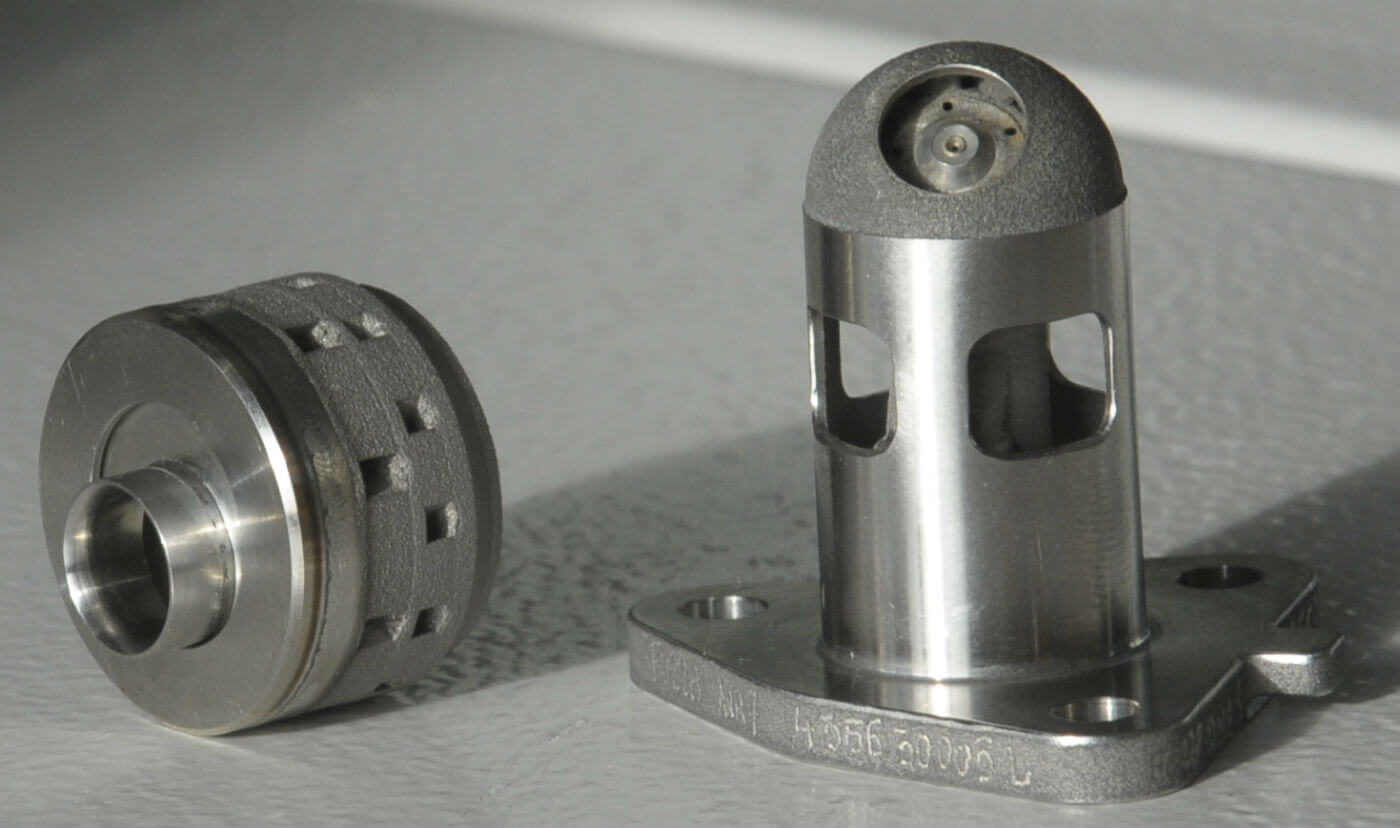

In future, additive manufacturing should be increasingly important and bring even greater benefits than in other industries, Even said. As their production rate is relatively low and because they are diverse, engine helicopter parts are well suited to 3D printing. This manufacturing process will represent one-third of the engine in 10 years, according to Even. Safran is already producing some parts with 3D printing, like swirlers for the Ardiden 3 and fuel nozzles for the Arrano. The former engine powers the Kamov Ka-62 and the Avicopter AC352, while the latter equips the Airbus H160 — all three aircraft in development.

Customer support may be perceived as less exciting, but it accounts for two-thirds of the company’s €1.3 billion ($1.5 billion) in revenues. And Safran is seeking innovation in services, too. Big data analytics is hoped to make an operator’s dream — predictive maintenance — come true. But it also opens a door for outsiders like startup companies specializing in such data processing. Safran believes it will have an edge thanks to its expert knowledge of the engines’ physics.