When Mitch Snyder, CEO of Bell Helicopter, unveiled the FCX-001 concept aircraft at Heli-Expo last year, he also revealed the creation of an innovation team to “explore ideas ahead of their time.”

It was a tacit admission that the company needed to return to its pioneering spirit — to reconnect with its innovative DNA, he said — and marked a noticeable shift in corporate thinking. More than a manufacturer of helicopters, Bell would also be at the forefront of emerging technologies.

The move is in part recognition that Bell Helicopter is in an open race to deliver the first proof of concept for an air taxi, and it has every intention of being a leader. It’s also acknowledgement that as more players from sectors such as artificial intelligence (AI), autonomous systems and quantum computing engage with aerospace, the sector could see significant disruption.

The FCX-001 was the result of a team of graphic designers, engineers and specialists in propulsion, electronics and avionics reimagining an anti-torque system in the tail boom, hybridized propulsion, more sustainable materials for an airframe able to harvest and manage energy, morphing rotor blades to optimize performance, and a flight deck controlled through augmented reality and an AI computer assistance system.

“The FCX-001 points the way for our future — a renewed focus on innovative solutions and technologies,” Snyder said at the time.

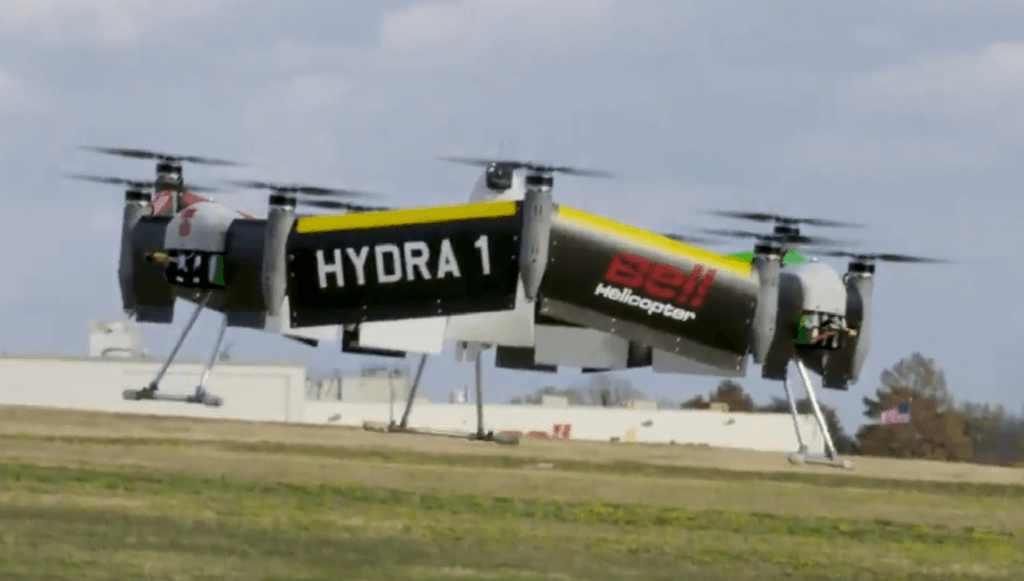

In January, Bell Helicopter demonstrated its latest concept project, Hybrid Drive Train Research Aircraft, or HYDRA, a circular unmanned aerial platform to research advanced distributed propulsion systems.

The ring-wing aircraft consists of 12 off-the-shelf KDE Direct motors, each producing 15 pounds of thrust and drawing up to 60 amps to rotate counter- or clockwise for stability. Nine motors are positioned on the ring of the carbon fiber skin and structure while three are located on a central axis. The skins are held together by 3D printed aluminum components, each designed with multi-functional purposes to connect skins, mount motors and/or support landing gear, and provide channels for wiring.

What separates the 55-pound HYDRA from a more conventional quad-rotor UAV is its seamless transition from vertical take-off and hover to flight by flipping forward.

“The idea is to take this concept and push it to the maximum,” explained Michel Dion, manager of innovation, during a recent tour of Bell’s production facility in Mirabel, Quebec. “Right now it is not mission driven . . . it’s really about innovation . . . playing with the parameters and the variables.”

Engineers have been exploring the ring or closed-wing aircraft since the early 1900s, but it’s only in recent years that materials have become light enough to make it work efficiently, Dion said. The intent of the project is to gather data on flight characteristics, including aircraft size, quantity and configuration of motors, and of blade shapes, as well as the strengths and properties of various materials.

“This wasn’t designed for any specific mission. It was to develop the ring-wing concept and learn the algorithms of the flight characteristics of this aircraft,” said Kevin Morris, the engineer behind the project.

But by understanding how the aircraft performs with distributed propulsion, they believe HYDRA may validate a range of missions, including passenger transportation.

“There are certain aerodynamic effects of using this type of shape,” said Dion. “It’s not only for an urban air taxi; we’re developing basic knowledge for multiple possible missions.”

For the autopilot system, Bell is working with ARA Robotique, a Montreal start-up with a strategic association to the École de technologie supérieure de Montréal. The partnership has benefited both parties, providing ARA access to other companies in the aerospace sector and Bell with an advanced skill set not resident in-house.

Dion said the focus of the project to date has been on “the hover part” and the team is now transitioning to forward flight. “We are working on developing the controllers for the three axis of control, developing the science for how can we control this type of aircraft with multiple rotors without having a pitch ability [for] each blade, just with the speed of each motor. When you are in hover, for example, the aircraft will act like a helicopter — the yaw, the pitch, the roll will act like a helicopter. At some point when we transition to wing borne, we have to tell the aircraft ‘You are not flying like an airplane.’ We have to make that transfer [of] movement of the aircraft.”

Test flight duration has been modest — about 25 minutes — and speed has been limited, but the aircraft has proved remarkably stable in hover and forward flight, even in strong cross winds. And while HYDRA includes flaps that could be used to control yaw in hover and roll while in flight, for the moment the team has not employed them, preferring to keep the number of moving parts to just the motors and blades.

“We have different props in mind so you can move more air,” said Morris. “We’re going to start playing with pitch. What is the ultimate pitch for this aircraft [to generate] forward speed?”

The project has been a collaboration between designers and engineers in Mirabel and Bell helicopter’s headquarters in Fort Worth, Texas. Where it ultimately leads will depend on what the team learns, said Dion. “We wanted to prove the concept and develop our knowledge first.”

But Bell often works with universities and industry consortia such as the Consortium for Aerospace Research and Innovation in Canada and, while it’s still at a low technology readiness level, the HYDRA platform could serve as a testbed for academic situational awareness, autonomy, and composite materials-related projects, he noted.